Jump to section: finishes / sculpting / inlays / hole patterns / pocket clips / filework

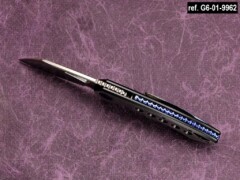

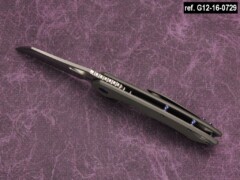

Blade Finish

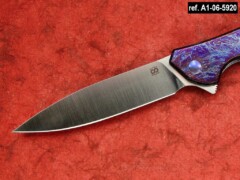

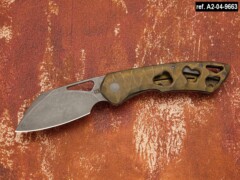

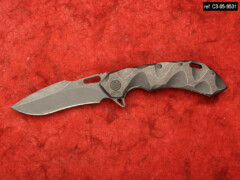

A2 ∙ Stonewash/dark acid stonewash

Stonewash finish in our two main styles which you'll see below are 1. light stonewash and 2. dark acid stonewash. The first will have a tighter wear/wash pattern, lighter gray color appearance, and is smooth to the touch. The second will be a deep dark gray with a looser wash pattern and a little bit more tactile feel to the touch.

A4 ∙ High polish

High polish finish blades pictured here are a rarer option and not available on all knives. Generally-speaking if you want a high polish blade you're looking at the following models: Rainmaker w/ harpoon compound or dagger blade, Wayfarer Classic, Wayfarer Compact.

Handle Finish

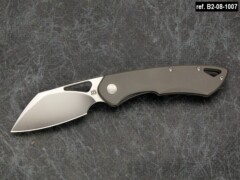

B2 ∙ Blasted (matte)

Matte, or media blast (typically ceramic) finishes are the most simple and offer a clean look on the titanium. Light blast retains more fingerprints and is smoother than dark blast, which has a small degree of tactility and will scratch easier (for a cool “pocket stonewash" look). Both blasts can be anodized to make matte blue, bronze, green, and purple colors. Please note that anodizing on a blasted finish will produce a more subdued color versus that on a satin or polished finish.

B3 ∙ Gunkote handles & parts

We experimented with and used a number of coatings in the past including PVD and Cerakote. In 2018 we discovered 2400 Series GunKote made by KG Industries and switched to it entirely both for blades and handles. We think it is a superior coating that offers infinite color flexibility. In addition to that we also have our own custom exclusive shade of matte black called Olamic Black. Below is a gallery of what is possible with this versatile coating. As of May 2019 we have brought this process in-house.

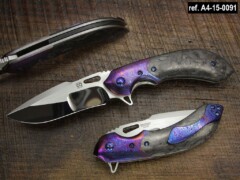

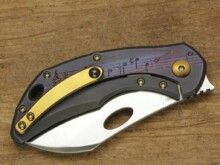

B5 ∙ Flame colored

Flame colored finish is exactly what it sounds like – we take a titanium frame and put a torch to it. The end result is always different and makes for a very tactical look without being just gray or black. Hand feel is similar to dark blast, it's matte with a very slight texture. This finish will show scratches with use and, as always, varies from knife to knife. We haven't made many knives with it and are still looking to explore its compatibility. So far we know it's possible with hole patterns, scalloping, and some sculpting but not with inlays.

B6 ∙ High polish

Titanium will take a nice polish, but not without effort. We have a number of options for a shinier, more glossy, more flash finish ranging. High polish is almost a mirror finish that can be done on flat or sculpted frames. Jeweled is a classic option that resembles engine turning, it plays very well with light, and is often hard to capture in photographs (but we try). Frosty is one of our newer options, a random non-circular type of jeweling that also has a slight texture. All of these can also be anodized however the shinier the finish the quicker anodizing will fade. Any full gloss finish will be more prone to finger prints except for Frosty, which doesn't show any.

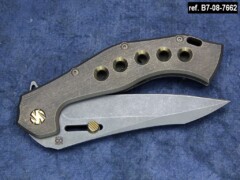

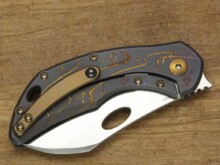

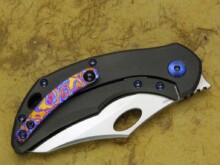

B7 ∙ Kinetic

Kinetic got its name at our shop because it involves so many steps, both physical around the shop, and literal in its creation to get the desired look. The end result is a somewhat tactile, fingerprint-friendly, woodgrain-like finish that's available in a number of colorways. If you look closely you'll see that Kinetic almost always features not one but two colors which means that they can be combined with other anodized accents on the knife. For example, Kinetic Rainforest is dominantly green but the secondary color can be either bronze or purple. We are always experimenting so don't be surprised if you notice that there are more types of Kinetic than what's pictured here. When ordering please refer to the exact photo of the Kinetic that you want so we know exactly what you're after. This finish can be combined with most handle options, but is not compatible with sculpting or inlays.

B8 ∙ Locomotive Breath *still in R&D*

This is a new finish for us and after some early variants we are still working out some of the kinks. For now (October 2020) we are not taking orders for knives with this finish until we further develop the method. Keep an eye out on our Instagram page or sign up for the newsletter to know when it's available again.

B9 ∙ Orange Peel

Orange peel is a lighter, smoother finish that has added tactility, can be anodized, and works with most other handle treatments. Anodizing on orange peel will not look the same as on a smooth or polished surface. Because of the texture, color will be less uniform, but instead show a mild spectrum between the dimples and tops of the texture itself. When anodized the color will fade somewhat until rubbed clean with a chamois cloth. Orange peel does remove some amount of titanium from the handle and therefore is not the best option if you're looking to change the finish to something else down the line. It can be combined with many handle options including inlays, hole patterns, and scalloping.

B10 ∙ Seabed

Seabed is a multi-step finish involving polishing and anodizing. It is only available on rock sculpted frames, backbars, and clips. In order to achieve its two-tone look and depth of color this style of sculpting is mandatory on the titanium itself. Seabed finish is characterized by having a deeper tone in the valleys and lighter, more polished tones in the peaks. It is very fingerprint friendly, does not fade easily, and works with most hole pattern options. Due to the nature of the sculpting, Seabed finish is not compatible with inlays.

B11 ∙ Splash anodized

This is a tricky but fun one and we do think Jackson Pollock would be proud. The end result cannot be predicted and most times we don't even know how we got there. Splash anodizing is very improvisational, so if this is something that you're after, you'll just have to trust us. It can be combined with some surface finishes, such as jeweling and high polish. When ordering please let us know what color scheme you're after.

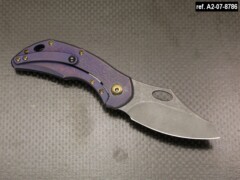

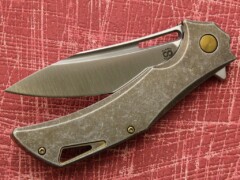

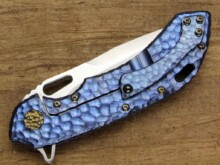

B12 ∙ Stonewash

Stonewash in all of its varieties is the most user-friendly option because its smoothness and worn look hides scratches very easily. Other times it will bring out depth out of sculpting or carving, for example our deep purple, which has just a hint of color. We have spent a lot of time perfecting our stonewash and believe that our current offering is the best possible option on our knives. Anodized and stonewash finishes are available in blue, green, purple, bronze. Due to the process such colorized S/W finishes will not have a uniform color but instead a semi-worn look. The color can fade as anodizing does naturally, but can be brought back using a hard wipe with a chamois cloth or a light wipe with acetone and a paper towel. There is an infinite amount of ways that stonewash can come out, so please keep in mind that its look will vary slightly from knife to knife.

Handle Sculpting

C1 ∙ Rock pattern

Rock sculpting or simply “rocks" is what we use to refer to random sculpting on titanium frames, backspacers, and clips. This style reduces slightly the weight of the knife and its handle thickness while allowing for a number of cool color/finish options. Our most popular and most visually appealing variant is rocks sculpting combined with Seabed finish which makes for darker valleys and lighter tops (highlights). This style is compatible with most hole options, especially Funky Holes. Please note that with standard holes the chamfers will not be perfect since for that the handle must be flat, and with rocks sculpting it isn't.

C2 ∙ Faux Bolsters

Faux bolster(s) refers to using a deep groove to separate the handle into sections. This method can create a single (front) faux bolster or double (front/rear) faux bolsters. The benefit here is that after the handle is segmented we can apply varying textures, sculpting, finishes, etc to each section creating an endless array of visually-striking combinations. Faux bolsters are possible on the presentation side, lock side, or both.

C4 ∙ Scalloped

Scalloped refers to a machined pattern on the frames on the Wayfarer 247 (only). This style reduces the weight of the knife by about 0.45oz and makes the handle thinner overall. There is a number of finishes available on scalloped frames, with high polish or orange peel being most effective.

C5 ∙ Molten

Molten is one of our signature styles and is a very versatile combination of carving, sculpting, finishing, and anodizing that's possible on most components of the knife. Because it is done by hand or with basic hand tools, Molten comes out different every time. This style gives titanium a soft, flowing, organic feel while adding grip and style. There are many finishes available on Molten including most colors of anodizing, light and dark blast, and stonewash. Because of the aggressive carving involved it is not possible to have inlays, pivot collars, and standard holes with Molten.

C6 ∙ Craters

Craters is more or less as the name implies: we apply deep, random craters to the entire handle or part of the handle. Due to the deep nature of this handle modification only a limited number of finishes are available, specifically most types of anodized and dark blasted ones. This style however works very well with single or double faux bolsters.

C7 ∙ Volcanic

Our latest sculpting style (June 2018) that is a modified version of Molten but with much deeper and more aggressive reliefs. This style is perfect for bright two tone anodizing, with darker valleys and polished tops. Available on all models.

Handle Inlays

D6 ∙ Dots dots dots

Dot inlays are a newer style for us and we're still exploring this elegant option. For this to work we need to have material in rod form and so far are limited to timascus, zirconium copper, and mokume but that doesn't mean we won't try something else. This style inlay works on flat handles in most finishes. If you don't see a dot inlay pattern that you like here, please contact us to see if your idea is possible.

D7 ∙ Pivot Collars

Similar to dot inlays, pivot collars involve material that is available as a cylindrical rod (timascus, zirconium, copper) and we are always looking for more options. Our preferred method is raised pivot collars which are possible on the presentation side, clip side, or both. We do these by hand so don't hesitate to ask what's possible even if you don't see it in the gallery below.

D8 ∙ Pocket inlays (Whippersnapper)

Weight Reduction

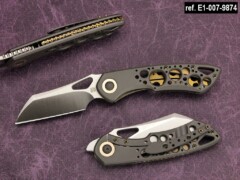

E1 ∙ Acid Rain

Acid Rain is what happens when we screw something up and is the most weight-reducing option available. After manually mis-drilling a hole we decided to keep going and cover the entire handle to mask the mistake. The end result became a style that evolved on its own, with multiple variants showcased below. Acid Rain is possible on the presentation side, clip side, pocket clip, and any combination of the three. Structural integrity of the knife is not jeopardized and weight reduction ranges 0.3-0.8oz. Generally this is possible on flat frames in most finishes, with or without anodized chamfers.

E2 ∙ Funky Holes

Funky Holes is what happens when we get a build request that we've never had before: to have a hole pattern on a non-flat (sculpted frame). After trying to get an even chamfer and failing we decided to salvage the knife by carving out the hole randomly by hand, to more match the sculpting style. The end result is what you see below. These holes can appear on the handle in a more uniform (in-line) pattern or spread randomly. Funky Holes are not possible on a flat frame and require some sculpting (Rocks or Molten) and cannot have anodized chamfers (since there aren't any).

E3 ∙ Hole Patterns

We use a manual mill/drill press to make our hole patterns which means there are many, many types. We'll spare you the time in reading a long list, but just consider the following… we have at least 4 possible hole sizes, 3 chamfer depths, multiple orientations, and 4 hole counts (odd numbers look best) spread across three models. For even hole chamfers you're better off with a flat handle and if you want something truly different please check out the next two sections (Funky Holes and Acid Rain).

Pocket Clips

F1 ∙ Wayfarer 247

The standard Wayfarer 247 pocket clip is titanium with a ceramic retention ball. It has full custom mounting hardware (screws) that were engineered specifically for the knife. The clip sits on standoffs that are threaded to screw into pockets in the frame then threaded and slotted again to allow the clip screws to attach. These standoffs are titanium just like the screws. There are tons of finishes available and many (but not all) are shown below. If you see something done the frames of the knife, chances are we can do it on the clip as well. Please also take a look at the 3D clip section below to see what else is possible using materials other than Titanium.

F2 ∙ Busker

The standard Busker pocket clip is titanium and comes in a variety of finishes. Most likely if you see the frames of the knife done a certain way then we can do the same on the clip. Mounting hardware (screws) are titanium as are the standoffs that the clip sits on. The standoffs are threaded and go into a recessed pocket in the frame. For better flexibility the Busker clip is also milled on the inside. Retention ball is ceramic. Please take a look at the hand sculpted 3D clip options in the section below this one to see what else is possible using materials other than Titanium.

F4 ∙ Swish

Pocket clip on the Swish model is Titanium, 3D-machined, with hidden hardware. It mounts into a pocket in the frames and is held by two screws on the inside. The retention ball is ceramic. If you see a finish on the frames or hardware of the knife then most likely we can duplicate it, or at least get very close, on the clip as well.

F5 ∙ Handmade 3D sculpted

We started to experiment with various other clip styles after seeing the variety of small pieces of fancy material left over from cutting out other parts of the knife. Because we make these clips entirely by hand one at a time there is no limit as to what they can look like. Their size and shape can vary and oftentimes the creation process is more improvisational. So far we've explored this style of custom 3D clip out of timascus, zirconium, damascus, and mokume but there is no limit to what we can try if the build calls for it.

F6 ∙ Cast stainless

We had an idea that we had to try: a pocket clip that's cast from stainless steel. Of course, why go through the trouble of such a complicated process for a basic one? So naturally we went with the most bad-ass option possible: skulls. These pocket clips work on the Wayfarer 247 and the Busker and are available in a number of finishes including a bold and durable gold Titanium Nitride (TiN) coating.

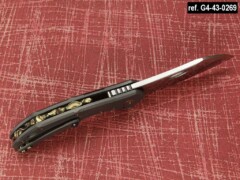

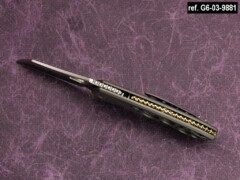

Backbars/Filework

Below you will find a few examples of the various styles of backspacer work that we offer. These patterns are filed or sculpted or carved into the titanium backbars by hand and can be finished in a number of ways depending on the style itself. Please explore the galleries below to see what's possible and as always don't hesitate to ask if you have an idea that's not pictured.